#Application Delivery Controller Market Segmentation

Explore tagged Tumblr posts

Text

Opioids Market Global Industry Analysis and Forecast (2023-2032)

Market Overview –

The opioids market is predicted to grow at a 5.4% CAGR between 2023 and 2032, reaching USD 6.93 billion.

The Opioids Market encompasses pharmaceutical drugs derived from opium or synthesized to mimic its effects, primarily used for pain management. Opioids are potent analgesics commonly prescribed for acute and chronic pain conditions, including postoperative pain, cancer-related pain, and severe injuries. However, the widespread use of opioids has led to concerns about addiction, overdose, and misuse.

The opioids market, while grappling with addiction concerns, sees a promising trend with the growing adoption of naltrexone. This medication offers a novel approach to managing opioid dependence by blocking opioid receptors, reducing cravings and withdrawal symptoms. As awareness rises, naltrexone's role in addiction treatment strengthens, contributing to a multifaceted approach to opioid management.

In recent years, the opioids market has witnessed significant growth globally due to several factors. Firstly, there has been increasing recognition of the need for effective pain management options, particularly in the context of aging populations and rising prevalence of chronic pain conditions. Key players in this market include pharmaceutical companies, healthcare providers, pain management clinics, and regulatory agencies, collaborating to develop and distribute opioids responsibly while mitigating risks of abuse and addiction.

Moreover, advancements in opioid formulations and delivery systems have led to the development of extended-release, abuse-deterrent, and non-opioid combination products. These innovations aim to improve pain control, reduce side effects, and minimize the potential for addiction and misuse.

Segment analysis

The segment study for the global opioids market is done by product, end-users, and applications. The product based segments of the opioids market are immediate-release/short-acting opioids and extended-release/long-acting opioids. The sub-segments of the extended-release opioid segment are morphine, oxycodone, oxymorphone, and hydromorphone among others. The extended-release opioid segment can value above USD 12,750.91 Mn by 2027. The sub-segments of the immediate-release opioid segment are hydrocodone, codeine, morphine, and fentanyl among others. The application-based segments of the opioids market are anesthesia, pain relief, diarrhoea suppression, cough suppression, and de-addiction. The end-user based segments of the global opioids market are pharmacies, academic research institutes, and hospitals & clinics. The end-user segments can largely benefit the opioids market.

Regional Analysis

The opioids market in Americas can secure the largest share of the worldwide global opioids market in the study period. The increase in the application of intravenous usage of opioids due to its fast action can promote the regional market rise in the near future. The growing awareness of IV application of opioids and its medical uses can drive the regional market in the near future. The market in Americas can accounted for the major share of the worldwide opioids market owing due rise in intravenous drug application. In Europe, the opioids market can thrive owing to the rise in demand for palliative care facilities. The introduction of reformed regulations for prescribing opioids can promote the market in the region. In Asia Pacific, the market is likely to be fast growing through the review period. Populace demographics and rise in availability of effective opioid medicines can favor the Asia Pacific opioids market in the analysis period. In South Korea, the market can secure about 6% of the APAC opioids market by 2027. In the Middle East and Africa region, a steady rise for the market is likely due to increase in count of opioid manufacturers in the region.

Key Players –

Opioids key players include Sanofi from France, Teva Pharmaceutical Industries from Israel, Bristol-Myers Squibb from the US, AbbVie Inc. from the US, Boehringer Ingelheim International GmbH from Germany, Purdue Pharma from the US, Astellas Pharma Inc. from Japan, Pfizer Inc. from the US, Biogen Idec from the US, Bayer from Germany, and GlaxoSmithKline from the UK.

Related Reports –

amniotic membrane market

asia pacific aesthetics market

diabetic nephropathy market

chronic kidney disease market

For more information visit at MarketResearchFuture

2 notes

·

View notes

Text

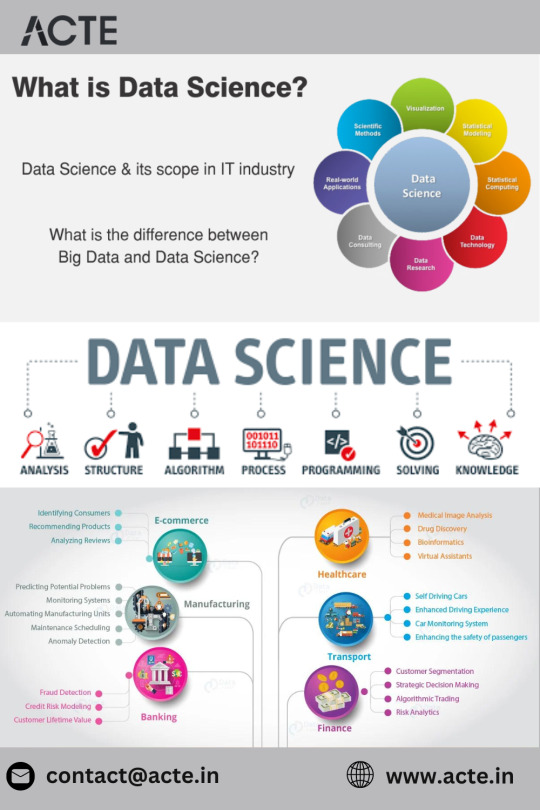

Data Science Unveiled: A Journey Across Industries

In the intricate tapestry of modern industries, data science stands as the master weaver, threading insights, predictions, and optimizations. From healthcare to finance, e-commerce to education, the applications of data science are as diverse as the sectors it transforms. Choosing the Top Data Science Institute can further accelerate your journey into this thriving industry. In this exploration, we'll embark on a journey to unravel the pervasive influence of data science across various domains, witnessing its transformative power and impact on decision-making in the digital age.

Healthcare: Pioneering Precision Medicine

In the healthcare sector, data science acts as a beacon of innovation. It plays a pivotal role in patient diagnosis, treatment optimization, and personalized medicine. By analyzing vast datasets, healthcare professionals can identify patterns, predict disease outcomes, and tailor treatments to individual patients. This not only enhances the efficiency of healthcare delivery but also contributes to groundbreaking advancements in medical research.

Finance: Navigating Risk and Detecting Fraud

The financial landscape is ripe for data science applications, particularly in risk management, fraud detection, and algorithmic trading. Data-driven models analyze market trends, assess risk exposure, and identify fraudulent activities in real-time. This not only safeguards financial institutions but also empowers them to make informed investment decisions, optimizing portfolios for better returns.

E-commerce: Crafting Personalized Experiences

In the bustling world of e-commerce, data science is the engine driving personalized experiences. Recommendation systems powered by data analysis understand user behavior, preferences, and purchase history. This results in tailored product suggestions, optimized pricing strategies, and a seamless shopping journey that boosts sales and enhances customer satisfaction.

Telecommunications: Enhancing Connectivity and Predicting Maintenance

Telecommunications companies leverage data science for network optimization, predictive maintenance, and customer churn analysis. By analyzing vast datasets, they can optimize network performance, predict potential issues, and proactively address concerns. This not only enhances the reliability of communication networks but also improves the overall customer experience.

Marketing: Precision in Targeting and Campaign Optimization

Marketers rely on data science for precision in targeting and campaign optimization. Customer segmentation, behavior analysis, and predictive modeling help marketers tailor their strategies for maximum impact. This ensures that marketing efforts are not only more effective but also cost-efficient, yielding higher returns on investment.

Education: Tailoring Learning Experiences

In the realm of education, data science is reshaping how students learn. Personalized learning experiences, performance analytics, and resource optimization are made possible through data analysis. By understanding student behavior and learning patterns, educators can tailor educational strategies to individual needs, fostering a more adaptive and effective learning environment.

Manufacturing: Predictive Maintenance and Quality Control

Manufacturing enterprises harness data science for predictive maintenance, quality control, and supply chain optimization. Analyzing data from sensors and production lines allows for predictive maintenance, minimizing downtime and reducing defects. This not only enhances operational efficiency but also contributes to cost savings. Choosing the best Data Science Courses in Chennai is a crucial step in acquiring the necessary expertise for a successful career in the evolving landscape of data science.

Energy: Sustainability and Operational Efficiency

Data science is a driving force in the energy sector, contributing to sustainability and operational efficiency. Predictive maintenance of equipment, analysis of energy consumption patterns, and optimization of energy production are facilitated through data-driven insights. This not only ensures reliable energy supply but also contributes to the global push for sustainable practices.

Transportation and Logistics: Optimizing Routes and Operations

In transportation and logistics, data science is instrumental in optimizing routes, predicting demand, and managing fleets efficiently. By analyzing data on traffic patterns, delivery times, and inventory levels, companies can optimize logistics operations, reduce costs, and improve overall service delivery.

Human Resources: Talent Acquisition and Workforce Planning

Human Resources (HR) departments utilize data science for talent acquisition, employee engagement analysis, and workforce planning. Analyzing data on employee performance, satisfaction, and recruitment processes enables HR professionals to make informed decisions, attract top talent, and optimize organizational performance.

Social Media: Enhancing User Engagement and Content Recommendation

Social media platforms leverage data science for enhancing user engagement and content recommendation. Algorithms analyze user interactions, preferences, and behaviors to recommend personalized content and improve overall user experience. This not only keeps users engaged but also enhances the platform's ability to deliver relevant content.

Government and Public Policy: Informed Decision-Making

In the realm of government and public policy, data science aids in informed decision-making. Analyzing data on various facets, including crime rates, resource allocation, and citizen services, enables governments to optimize policies for the welfare of the public. This data-driven approach enhances governance and contributes to more effective public services.

As we traverse the vast landscape of industries, it becomes evident that data science is not merely a tool but a transformative force that connects and elevates diverse sectors. Its ability to extract insights, predict outcomes, and optimize processes is reshaping the way businesses and institutions operate. In an era defined by data, data science stands as a thread weaving through the fabric of innovation, connecting industries and shaping the future of decision-making. As we continue to explore the frontiers of technology, the influence of data science is set to expand, leaving an indelible mark on the evolution of industries across the globe.

3 notes

·

View notes

Text

Emerging Markets Drive Acceleration in Live Vaccine Deployment

The Live Attenuated Vaccines Market is experiencing rapid expansion, projected to grow from USD 25.3 billion in 2023 to USD 70.4 billion by 2032. The market is driven by increased demand for robust, long-lasting immunizations, innovations in oral and intranasal delivery systems, and rising infectious disease threats worldwide. Growth is especially strong in the United States, Japan, and across Asia-Pacific, as governments increase funding and regulatory support for advanced vaccine development and deployment.

To Get Free Sample Report : https://www.datamintelligence.com/download-sample/live-attenuated-vaccines-market

Key Growth Drivers

Rising Prevalence of Infectious Diseases Global disease outbreaks from measles and polio to newer respiratory viruses are increasing the urgency of effective immunization. Live attenuated vaccines, which mimic natural infections without causing disease, are particularly effective at building durable immunity and reducing transmission.

Dominance of Viral Vaccine Applications Live attenuated vaccines are primarily used for viral infections such as measles, mumps, rubella (MMR), polio, varicella, rotavirus, and influenza. This segment accounts for the largest share of the market and continues to expand rapidly, especially in childhood immunization programs and seasonal flu protection.

Advancements in Vaccine Delivery Methods Non-injectable delivery platforms especially intranasal and oral vaccines are revolutionizing immunization. These formats are preferred for mass immunization due to convenience, pain-free administration, and ability to induce mucosal immunity. Products like the intranasal flu vaccine are already seeing strong uptake.

Multivalent Vaccine Development New multivalent live attenuated vaccines targeting multiple diseases in a single dose are reshaping global vaccination strategies. These vaccines improve efficiency, lower logistical costs, and are ideal for pediatric and elderly patients who benefit from fewer injections.

Supportive Public Health Initiatives Government-driven vaccination programs, such as the Expanded Programme on Immunization (EPI) and pandemic response frameworks, continue to prioritize live attenuated vaccines. Regulatory agencies across North America, Europe, and Asia are accelerating the approval process for next-generation vaccines.

Regional Insights

North America The U.S. remains at the forefront of live attenuated vaccine innovation. Strong R&D infrastructure, government funding for vaccine development, and early adoption of new technologies keep North America a leading market. Seasonal influenza and MMR vaccine usage continues to rise, and the COVID-19 pandemic has boosted long-term public trust in vaccination programs.

Japan and Asia-Pacific Asia-Pacific is expected to register the fastest growth. Japan has a robust track record in producing intranasal and oral vaccines, while China and India are scaling up domestic manufacturing for public health deployment. Government funding for pediatric and adult immunization programs is growing throughout the region, supported by a rising middle-class population and healthcare reforms.

Europe European countries maintain high vaccine coverage rates, supported by centralized immunization schedules and strong regulatory support. Live vaccines remain central to disease control programs in Germany, France, Italy, and the UK, especially for measles, rotavirus, and influenza.

Market Segmentation Highlights

By Type

Viral Vaccines: Account for the majority of market share, including vaccines for measles, flu, varicella, and rubella.

Bacterial Vaccines: A smaller but growing segment focused on diseases like tuberculosis and typhoid.

By Method of Development

Tissue Culture-Based: Preferred method due to high yield and safety; holds the largest share.

Egg-Based and In Vivo: Still used for specific vaccines like seasonal flu but declining due to scalability and safety concerns.

By Delivery Route

Injectable: Dominant method but slowly losing share to needle-free alternatives.

Oral and Intranasal: Fastest-growing segments due to their ease of use and suitability for mass campaigns.

By End User

Hospitals and Clinics: Main distribution channels, particularly for government-backed immunization.

Diagnostic Centers and Specialty Clinics: Gaining traction in urban areas and private sector healthcare.

Emerging Opportunities

Needle-Free Vaccination Expansion Growing demand for patient-friendly vaccine formats is pushing the adoption of intranasal and oral vaccines, particularly in pediatrics, geriatrics, and school health programs.

AI and Digital Tools in Vaccine Design Artificial intelligence and machine learning are accelerating antigen identification, improving immune response modeling, and reducing time-to-market for complex vaccine formulations.

Multivalent and Personalized Vaccines New platforms allow for combined vaccines that target multiple diseases. Personalized vaccine technologies based on genomics and regional disease patterns are expected to rise in coming years.

Pandemic-Ready Platforms Countries are investing in live attenuated vaccine platforms that can be quickly adapted during future outbreaks. These platforms are favored for their scalable production and rapid immune response capabilities.

Get the Demo Full Report : https://www.datamintelligence.com/enquiry/live-attenuated-vaccines-market

Challenges

Cold Chain Limitations: Maintaining live vaccine potency requires temperature-controlled logistics, a challenge in rural or low-resource regions.

Safety Monitoring: Though rare, there is a small risk of reversion to virulence or adverse reactions, requiring strong post-market surveillance systems.

Regulatory Hurdles: Regional regulatory variations can slow down market entry. Harmonized approval pathways are needed for rapid global distribution.

Public Misinformation: Vaccine hesitancy in some countries, driven by misinformation, remains a barrier that stakeholders must address through transparent communication.

Conclusion

The live attenuated vaccines market is poised for robust growth, nearly tripling from USD 25.3 billion in 2023 to USD 70.4 billion by 2032. With innovations in vaccine formulation, needle-free delivery systems, and rapid-response manufacturing capabilities, live vaccines are expected to remain a cornerstone of public health for the foreseeable future.

As demand grows across developed and developing economies, supported by government initiatives and global health organizations, companies investing in next-generation live vaccine platforms, personalized solutions, and AI-driven design are best positioned to lead the market into the next decade.

0 notes

Text

USA Opioids Drug Market 2024–2031 | $3,175M Market Starting Value & Growth Forecast

Market Overview

According to recent industry analysis, the USA opioid drug market reached a valuation of USD 9.58 billion in 2023 and is forecasted to grow to USD 13.02 billion by 2031, reflecting a compound annual growth rate (CAGR) of 4.0% during the forecast period of 2024 to 2031.

This upward trend is attributed primarily to the increasing demand for effective chronic pain management, especially in cancer patients, surgical recovery, and palliative care. Opioids, despite their associated risks, continue to play a pivotal role in advanced therapeutic settings due to their superior efficacy in controlling moderate to severe pain.

To buy the report, click on https://www.datamintelligence.com/buy-now-page?report=usa-opioids-drug-market

What Are Opioid Drugs?

Opioid drugs are potent pain-relieving medications that work by binding to specific opioid receptors in the brain and nervous system. This interaction modifies how the body interprets pain, offering relief from intense discomfort.

Common prescription opioids include:

Morphine

Oxycodone

Hydrocodone

Fentanyl

Codeine

Hydromorphone

Propoxyphene

While highly effective, opioids are associated with risks such as physical dependence, withdrawal symptoms, and in some cases, addiction or overdose—especially when used over prolonged periods or outside medical supervision.

To get the free sample report, click on https://www.datamintelligence.com/download-sample/usa-opioids-drug-market

Market Growth Drivers

Rising Prevalence of Chronic Pain and Cancer

One of the biggest contributors to market growth is the increasing burden of chronic diseases such as cancer, arthritis, and neurological disorders.

According to the National Cancer Institute, approximately 2 million new cancer cases are expected in the U.S. in 2024. Painful treatments like chemotherapy and post-surgical care often require potent analgesics, positioning opioids as the gold standard for effective relief.

Technological Advancements and New Formulations

Pharmaceutical companies are innovating in abuse-deterrent formulations (ADFs) to make opioid misuse less feasible. These include:

Extended-release versions

Tamper-resistant pills

Smart drug delivery systems

Government Guidelines and Hospital Protocols

Strict prescription monitoring programs and public health campaigns have reshaped prescription practices. However, for hospital-grade pain management, particularly post-surgery and in terminal illness care, opioids remain indispensable.

Challenges Restraining the Market

Despite growth, the market faces headwinds:

Adverse Effects: Opioid usage can cause nausea, vomiting, constipation, drowsiness, and in severe cases, respiratory depression.

Dependence and Abuse Risk: Long-term usage often leads to physical dependence, and abrupt discontinuation can result in withdrawal symptoms.

Regulatory Pressures: Federal and state governments are imposing stricter regulations and prescription caps to prevent abuse.To get the unlimited market intelligence, subscribe https://www.datamintelligence.com/buy-now-page?report=usa-opioids-drug-market

Market Segmentation

The U.S. opioids drug market is segmented by drug type, application, and end-user.

By Drug Type:

Codeine

Oxycodone

Hydrocodone

Fentanyl

Morphine

Hydromorphone

Propoxyphene

Others

By Application:

Pain Relief (dominant segment with 67.5% market share)

Anesthesia

Cough Suppression

Diarrhea Suppression

De-addiction

By End-User:

Hospitals and Clinics

Academic and Research Centers

De-addiction Centers

Others

Pain relief continues to dominate the application segment, driven by its role in post-surgical care and chronic illness management.

Industry Landscape and Key Players

The U.S. opioids drug market is highly consolidated, with leading pharmaceutical players actively investing in research and regulatory compliance. Major companies include:

Pfizer Inc.

Purdue Pharma L.P.

Johnson & Johnson Services Inc.

Hikma Pharmaceuticals PLC

Sanofi

Abbvie Inc.

Merck KGaA

Viatris Inc.

Teva Pharmaceutical Industries Ltd.

Endo Inc.

These firms are focusing on new product development, strategic partnerships, and mergers & acquisitions to expand their footprint and comply with evolving FDA standards.

Recent Developments and Industry Trends

In January 2022, Trevena, Inc. announced that the Chinese NMPA accepted the New Drug Application for oliceridine injection, approved by the U.S. FDA for treating chronic pain severe enough to require intravenous opioids.

Hospitals and clinics are increasingly demanding tamper-proof opioid formulations to ensure safer inpatient care.

The market is seeing a rise in telehealth-based pain management programs, which pair digital consultations with opioid prescribing under monitored conditions.

Future Outlook

With rising demand in oncology, orthopedic surgeries, and end-of-life care, the U.S. opioid drug market is poised to grow steadily. However, future expansion hinges on:

Continued innovation in abuse-deterrent formulations

Stricter post-marketing surveillance to track misuse

Integration with non-opioid alternatives to create multi-modal pain therapies

Healthcare professionals are increasingly adopting balanced pain management strategies that combine opioids with physical therapy, cognitive behavioral therapy (CBT), and non-opioid medications.

About Us

DataM Intelligence is a leading provider of global business intelligence, offering actionable insights and in-depth market analysis across healthcare, pharmaceuticals, and biotechnology sectors. Our team of experienced researchers, analysts, and subject matter experts delivers high-quality syndicated and custom research reports designed to empower decision-makers.

From tracking emerging technologies and competitive landscapes to delivering comprehensive regulatory insights, we help our clients stay ahead in rapidly evolving industries.

Contact Us

DataM Intelligence Email: [email protected]

Phone: +1 877 441 4866

0 notes

Text

Pilot Air Control Valves Market: Cost-Benefit Analysis for Infrastructure Projects

MARKET INSIGHTS

The global Pilot Air Control Valves Market size was valued at US$ 2,340 million in 2024 and is projected to reach US$ 3,870 million by 2032, at a CAGR of 7.51% during the forecast period 2025-2032. The U.S. market accounted for 28% of global revenue in 2024, while China is expected to grow at a faster CAGR of 6.7% through 2032 due to increasing industrial automation.

Pilot Air Control Valves are precision pneumatic components that regulate compressed air flow in industrial systems through pilot-operated mechanisms. These valves are categorized into 2-way, 3-way, and 4-way configurations, each designed for specific directional control applications in pneumatic circuits. The 2-way segment currently dominates with over 42% market share, driven by widespread use in basic on/off applications across manufacturing facilities.

The market growth is primarily fueled by accelerating industrial automation across sectors, particularly in automotive and electronics manufacturing. However, supply chain disruptions for raw materials like aluminum and brass have created pricing pressures. Key players including Parker Hannifin and SMC Corporation are addressing these challenges through strategic acquisitions – Parker’s 2023 purchase of Clippard strengthened its position in miniature valve solutions, while SMC expanded its Asian production capacity by 15% in early 2024 to meet growing regional demand.

MARKET DYNAMICS

MARKET DRIVERS

Expansion of Industrial Automation to Accelerate Pilot Air Control Valve Adoption

The global industrial automation sector is experiencing unprecedented growth, with investments projected to exceed $400 billion annually by 2030. Pilot air control valves serve as critical components in automated pneumatic systems, enabling precise regulation of air pressure and flow in manufacturing processes. This surge in automation adoption across industries ranging from automotive to food processing is directly translating to increased demand for high-performance control valves. The valves’ ability to ensure operational efficiency while minimizing energy consumption makes them indispensable in modern automated facilities. Furthermore, stringent quality standards in industries such as pharmaceuticals and electronics manufacturing are compelling organizations to upgrade their pneumatic systems with advanced control valve solutions.

Aerospace Sector Modernization to Fuel Valve Demand

The aerospace industry is undergoing significant fleet modernization efforts, with aircraft manufacturers increasing production rates to meet rebounding post-pandemic travel demand. Pilot air control valves play crucial roles in aircraft systems including cabin pressure regulation, landing gear operation, and auxiliary power units. With commercial aircraft deliveries expected to grow at 7% CAGR through 2030, component suppliers are facing tremendous pressure to scale production. The valves’ lightweight construction and reliability under extreme conditions make them particularly valuable in aerospace applications. Additionally, the expansion of space exploration programs worldwide is creating new opportunities for specialized valve solutions capable of performing in zero-gravity environments.

➤ For instance, recent advancements in additive manufacturing have enabled production of control valves with 40% weight reduction while maintaining structural integrity for aerospace applications.

MARKET RESTRAINTS

Supply Chain Disruptions to Impact Market Growth

While demand continues to accelerate, the pilot air control valve market faces significant supply-side challenges. The industry remains vulnerable to global supply chain disruptions affecting raw material availability, particularly for specialized alloys and precision components. Recent geopolitical tensions have exacerbated lead times for critical materials, with some manufacturers reporting 60-90 day delays in component deliveries. These disruptions are forcing companies to either carry higher inventory levels or redesign products to accommodate available materials – both approaches increasing production costs. Smaller manufacturers without diversified supplier networks are especially vulnerable to these market pressures.

Other Restraints

Price Sensitivity in Emerging Markets

Cost competitiveness remains a significant barrier in price-sensitive regions where end-users often prioritize initial purchase price over total cost of ownership. This creates challenges for manufacturers attempting to introduce advanced valve solutions with superior longevity and efficiency characteristics.

Regulatory Compliance Burdens

Increasing environmental and safety regulations across multiple jurisdictions require continuous product recertification, adding to development timelines and compliance costs for manufacturers operating in global markets.

MARKET CHALLENGES

Technological Specialization Straining Workforce Development

The industry faces a critical shortage of skilled technicians capable of designing, manufacturing, and maintaining increasingly sophisticated pilot air control valve systems. As valve technology incorporates more electronic components and smart capabilities, the required skill sets have expanded beyond traditional mechanical engineering. Training programs have struggled to keep pace with these evolving requirements, resulting in talent gaps particularly in specialized areas like materials science and fluid dynamics simulation. The challenge is compounded by an aging workforce, with many experienced valve engineers approaching retirement without adequate successors in place.

Other Challenges

Integration With IIoT Systems The rapid adoption of Industrial Internet of Things (IIoT) technologies presents both opportunities and challenges. While smart valve solutions promise enhanced monitoring and predictive maintenance capabilities, many legacy industrial facilities lack the infrastructure to support these advanced systems.

Precision Engineering Requirements Modern applications demand valves with micron-level precision and extremely tight tolerances, pushing manufacturing capabilities to their limits and requiring substantial investments in production equipment upgrades.

MARKET OPPORTUNITIES

Emergence of Smart Factory Concepts to Drive Next-Generation Valve Development

The transition toward Industry 4.0 is creating significant opportunities for innovation in pilot air control valve technology. Smart valves equipped with sensors, wireless connectivity, and embedded diagnostics are increasingly becoming integral components of connected manufacturing environments. These intelligent systems enable real-time performance monitoring, predictive maintenance, and automatic adjustments to optimize energy efficiency. Market leaders are investing heavily in R&D to develop valves that can seamlessly integrate with digital twin simulations and autonomous control systems. The predictive maintenance segment alone for industrial valves is projected to grow at nearly 20% CAGR through the decade, representing a major growth avenue for forward-thinking manufacturers.

Expansion in Emerging Economies Opens New Growth Frontiers

Rapid industrialization across developing markets presents substantial expansion opportunities. Countries in Southeast Asia and Africa are investing heavily in manufacturing infrastructure, with Indonesia, Vietnam, and Nigeria emerging as particularly promising markets. These regions offer attractive growth potential due to lower market saturation and increasing domestic capability to support industrial operations. Local production initiatives in these markets also create opportunities for technology transfer and joint venture partnerships. Strategic geographic expansion combined with product adaptations to meet regional requirements could yield significant returns for valve manufacturers.

PILOT AIR CONTROL VALVES MARKET TRENDS

Industry 4.0 Integration Revolutionizing Pilot Air Control Valve Market

The adoption of Industry 4.0 technologies is transforming the pilot air control valves market, particularly in industrial automation applications. Smart valves with integrated IoT sensors now account for over 30% of new installations in developed markets, enabling real-time pressure monitoring and predictive maintenance. These advanced valves reduce downtime by up to 40% while improving energy efficiency in pneumatic systems. Manufacturers are increasingly incorporating wireless connectivity features, with the industrial sector showing 25% year-over-year growth in demand for networked valve solutions. The transition towards digital factories has created substantial opportunities for intelligent valve systems that can integrate with broader automation architectures.

Other Trends

Energy Efficiency Standards Driving Product Innovation

Stricter global energy regulations are compelling manufacturers to develop more efficient pilot air control valve designs. New ceramic-sealed valves have demonstrated 15-20% better energy retention compared to traditional metal-seated models, particularly in high-cycle applications. The European Union’s Ecodesign Directive has accelerated development of low-leakage valves, with the commercial building sector showing particular interest in these solutions. Furthermore, compact valve designs with reduced internal volume now account for nearly 45% of the aerospace market segment, where weight and energy savings are critical performance factors.

Material Science Advancements Enhancing Valve Performance

Recent breakthroughs in materials engineering are significantly improving the durability and functionality of pilot air control valves. The commercial introduction of graphene-enhanced polymer composites has extended valve lifespans by 3-5 times in high-wear applications. Meanwhile, high-performance alloys resistant to corrosion now enable reliable valve operation in harsh environments, driving adoption in oil and gas applications. The market has seen particular growth in ultra-clean valves for semiconductor manufacturing, where particle generation must be minimized. These material innovations are particularly impactful in the 3-way valve segment, which represents about 32% of total market value.

COMPETITIVE LANDSCAPE

Key Industry Players

Leading Manufacturers Focus on Innovation & Regional Expansion to Capture Market Share

The global Pilot Air Control Valves market exhibits a moderately fragmented competitive landscape, with established industrial automation giants competing alongside specialized pneumatic component manufacturers. Parker Hannifin Corporation maintains a dominant position, commanding approximately 18% of the 2024 market revenue share due to its comprehensive product range spanning 2-way, 3-way, and 4-way valve configurations.

Emerson Electric Co. and SMC Corporation collectively held nearly 27% of the global market last year. Their strong performance stems from vertical integration capabilities and extensive distribution networks across industrial and aerospace sectors. Emerson’s recent acquisition of pneumatic component startups has particularly strengthened its IoT-enabled valve offerings.

While these industry leaders continue to dominate, mid-sized players like Festo and NUMATICS are gaining traction through niche specialization. Festo’s energy-efficient valve designs have captured 9% of the European market, whereas NUMATICS saw 12% year-over-year growth in North America through customized industrial solutions.

Meanwhile, Asian manufacturers such as AirTAC and KOGANEI Corporation are disrupting pricing structures. AirTAC’s 2023 financial reports indicate a 23% production cost advantage over Western counterparts, enabling aggressive expansion in emerging markets. However, trade barriers and quality perception challenges continue to limit their premium segment penetration.

List of Key Pilot Air Control Valve Manufacturers

Parker Hannifin Corporation (U.S.)

Emerson Electric Co. (U.S.)

SMC Corporation (Japan)

NITRA Pneumatics (Slovakia)

Pneumadyne, Inc. (U.S.)

NUMATICS (U.S.)

Clippard Instrument Laboratory, Inc. (U.S.)

ARO (Ingersoll Rand) (U.S.)

Humphrey Products (U.S.)

Festo (Germany)

KOGANEI Corporation (Japan)

AirTAC (Taiwan)

The competitive intensity continues to rise as manufacturers balance performance enhancements with cost reduction pressures. While industrial applications drive volume sales, aerospace-grade valves generate higher margins, prompting firms to develop dual-certification products. Recent developments show established players forming technology partnerships with automation software providers to deliver smart valve solutions, whereas regional specialists focus on distribution network expansions.

Segment Analysis:

By Type

2-Way Segment Leads Due to Wide Adoption in Industrial Automation

The market is segmented based on type into:

2-Way

Subtypes: Normally Open, Normally Closed

3-Way

4-Way

By Application

Industrial Applications Dominate Market Share Owing to High Demand in Manufacturing Processes

The market is segmented based on application into:

Industrial

Subtypes: Pneumatic Systems, Process Control

Aerospace

Others

By Material

Brass Segment Holds Largest Market Share Due to Corrosion Resistance Properties

The market is segmented based on material into:

Brass

Stainless Steel

Aluminum

Plastic

By End-Use Industry

Manufacturing Sector Accounts for Significant Market Share

The market is segmented based on end-use industry into:

Oil & Gas

Chemical Processing

Food & Beverage

Pharmaceutical

Others

Regional Analysis: Pilot Air Control Valves Market

North America The North American market for pilot air control valves is driven by advanced manufacturing practices and strict industrial automation standards. The U.S. accounts for the largest share within the region, supported by strong demand from the aerospace and industrial sectors—key end-users of precision pneumatic components. Regulatory standards, such as ASME B16.34, ensure product reliability, which further boosts adoption. Critical infrastructure projects, including energy and automation, propel demand. However, pricing pressures due to competition from Asian manufacturers pose challenges. Major players like Parker and Emerson dominate through continuous innovation in valve efficiency and smart control integration.

Europe Europe emphasizes energy-efficient pneumatic solutions, aligning with EU Green Deal initiatives targeting carbon-neutral industries. Germany and France lead the regional market due to their robust manufacturing bases, particularly in automotive and industrial automation. Stringent environmental norms accelerate the shift toward low-emission pneumatic valves, with companies like Festo and SMC Corporation investing in sustainable designs. The growing adoption of Industry 4.0 practices supports smart valve integration. However, high production costs and economic uncertainties in Eastern Europe moderate growth. Collaborative R&D efforts between universities and manufacturers drive technological advancements.

Asia-Pacific Asia-Pacific represents the fastest-growing market, led by China’s massive industrial expansion and Japan’s dominance in high-precision valve manufacturing. The region benefits from cost-competitive production and rising automation across industries like electronics and automotive. SMC Corporation and AirTAC hold significant market shares due to localized production advantages. While 3-way and 4-way valves dominate industrial applications, infrastructure investments in Southeast Asia open new opportunities. Challenges include inconsistent quality standards and intellectual property concerns. Government initiatives to enhance manufacturing capabilities, such as India’s “Make in India”, further fuel regional demand.

South America South America experiences steady growth, supported by Brazil’s industrial sector and mining applications. The adoption of modular pneumatic systems in food processing and agriculture drives demand. However, economic instability and currency fluctuations limit large-scale investments, leading to reliance on imports. Local manufacturers focus on cost-effective solutions, but technological gaps persist. Infrastructure projects in Argentina and Colombia may create opportunities, though political uncertainties slow market expansion. Partnerships with global players aim to improve technical capabilities in valve automation.

Middle East & Africa The MEA market remains nascent but promising, driven by oil & gas and water management applications. The UAE and Saudi Arabia lead with smart city projects requiring advanced pneumatic controls. High dependency on imports and limited local expertise hinder rapid adoption, though governments are incentivizing industrial diversification. Demand for durable valves in harsh environments presents growth potential. Regional players face challenges in competing with global suppliers due to budget constraints. Long-term infrastructure plans, like Saudi Arabia’s Vision 2030, are expected to gradually boost the market.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Pilot Air Control Valves markets, covering the forecast period 2024–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global market was valued at USD 287.5 million in 2024 and is projected to reach USD 398.2 million by 2032 at a CAGR of 4.8%.

Segmentation Analysis: Detailed breakdown by product type (2-Way, 3-Way, 4-Way), application (Industrial, Aerospace, Others), and end-user industry to identify high-growth segments and investment opportunities. The 2-Way segment is expected to dominate with over 42% market share by 2032.

Regional Outlook: Insights into market performance across North America (U.S. market size estimated at USD 78.4 million in 2024), Europe, Asia-Pacific (China projected to reach USD 112.6 million by 2032), Latin America, and the Middle East & Africa, including country-level analysis where relevant.

Competitive Landscape: Profiles of leading market participants including Parker, Emerson, SMC Corporation, NITRA, and Pneumadyne, Inc., covering their product offerings, R&D focus, manufacturing capacity, pricing strategies, and recent developments such as mergers, acquisitions, and partnerships. The top five players held approximately 58% market share in 2024.

Technology Trends & Innovation: Assessment of emerging technologies in valve automation, smart control systems, IoT integration, and evolving industry standards for pneumatic systems.

Market Drivers & Restraints: Evaluation of factors driving market growth (industrial automation, aerospace sector expansion) along with challenges (supply chain constraints, raw material price volatility).

Stakeholder Analysis: Insights for component suppliers, OEMs, system integrators, investors, and policymakers regarding the evolving ecosystem and strategic opportunities in the pneumatic control systems market.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/laser-diode-cover-glass-market-valued.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/q-switches-for-industrial-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ntc-smd-thermistor-market-emerging_19.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/lightning-rod-for-building-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/cpe-chip-market-analysis-cagr-of-121.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/line-array-detector-market-key-players.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/tape-heaters-market-industry-size-share.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/wavelength-division-multiplexing-module.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/electronic-spacer-market-report.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/5g-iot-chip-market-technology-trends.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/polarization-beam-combiner-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/amorphous-selenium-detector-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/output-mode-cleaners-market-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digitally-controlled-attenuators-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/thin-double-sided-fpc-market-key.html

0 notes

Text

Pharmaceutical Breakthroughs: The Expanding Role of Industrial Starch in Modern Medicine

The pharmaceutical industry's rapid evolution is creating unprecedented opportunities within the industrial starch market, as manufacturers discover innovative applications for starch-based excipients in drug formulation and delivery systems.

The Foundation of Modern Drug Development

Starch has become an indispensable component in pharmaceutical manufacturing, serving multiple critical functions that ensure drug efficacy and patient safety. As a disintegrant, it enables tablets to break down efficiently in the digestive system, ensuring optimal drug absorption. Its binding properties provide structural integrity to capsules and tablets, while its role as a filler helps achieve precise dosage requirements.

The industrial starch market is experiencing significant expansion in pharmaceutical applications, particularly with the growing demand for pregelatinized starch varieties. These specialized forms offer superior compressibility and flow properties, making them ideal for modern tablet production processes that require consistent quality and efficiency.

Global Manufacturing Expansion

Emerging markets are driving substantial growth in pharmaceutical starch applications. Countries including India, China, and Brazil have become major pharmaceutical manufacturing hubs, leveraging cost-effective production capabilities and serving rapidly growing patient populations.

This geographic expansion is creating new demand patterns within the industrial starch market, as pharmaceutical companies in these regions require high-quality starch derivatives for generic drug production, over-the-counter medications, and advanced sustained-release formulations.

Technological Advancements in Drug Delivery

The pharmaceutical sector's innovation in controlled-release drug delivery systems is opening new frontiers for starch applications. Modified starch formulations are enabling pharmaceutical companies to develop medications that release active ingredients over extended periods, improving patient compliance and therapeutic outcomes.

Know More : Industrial Starch Market Size, Share, Growth Trends, Revenue Forecast 2030

These advanced applications require specialized starch modifications that can withstand varying pH levels and moisture conditions while maintaining consistent release profiles. Such technical requirements are driving research and development investments throughout the industrial starch market, fostering innovation that benefits both manufacturers and patients.

Quality Standards and Regulatory Compliance

The pharmaceutical industry's stringent quality requirements are elevating standards across the entire industrial starch market. Pharmaceutical-grade starch must meet rigorous purity specifications, undergo extensive testing, and maintain consistent performance characteristics.

This emphasis on quality is creating opportunities for starch manufacturers who invest in advanced processing technologies and quality control systems. Companies that can consistently deliver pharmaceutical-grade products are positioning themselves for premium market segments with higher profit margins and long-term customer relationships.

Market Dynamics and Future Projections

The convergence of demographic trends, technological advancement, and regulatory evolution is creating a favorable environment for pharmaceutical applications within the industrial starch market. An aging global population requires more medications, while emerging markets are expanding access to healthcare services.

Generic drug production continues to grow rapidly, creating steady demand for cost-effective, high-quality starch excipients. Simultaneously, the development of novel drug delivery systems is generating requirements for specialized starch modifications that can support advanced therapeutic approaches.

The pharmaceutical sector's growth trajectory suggests that starch applications in medicine will continue expanding, driven by innovation in drug formulation, increasing global healthcare access, and the ongoing development of personalized medicine approaches that require flexible, adaptable excipient solutions.

As pharmaceutical companies continue to innovate and expand globally, the industrial starch market is poised to play an increasingly vital role in delivering safe, effective medications to patients worldwide.

0 notes

Text

Messenger RNA Market Landscape and Strategic Forecast

The messenger RNA market has rapidly emerged as a transformative segment within biotechnology and pharmaceuticals, driven by groundbreaking advancements in genetic research and vaccine development. With the success of COVID-19 vaccinations, mRNA technology—which allows the body to manufacture its own therapeutic proteins—became well-known worldwide. Applications have expanded beyond infectious diseases to encompass cancer, genetic abnormalities, and personalized medicine as a result of this success, which has also encouraged investment and innovation. With more regulatory support and continuing clinical trials, the mRNA industry is expected to increase significantly. The market is growing because major industry players are making significant investments in R&D, manufacturing capacity, and strategic partnerships. With quicker, more precise, and more scalable therapy choices, mRNA has the potential to completely transform modern medicine as the technology advances.

The Messenger RNA Market is expected to grow at a significant rate due to advancements in diagnostic technologies, the development of innovative therapies, and increasing awareness among patients and healthcare providers.

Market Drivers

Technological Advancements:Initial constraints are being addressed by ongoing developments in mRNA delivery technologies, stability improvement, and immunogenicity reduction. These advancements are opening the door to safer and more efficient treatments.

Growing Vaccine Demand: The COVID-19 pandemic has increased interest in and investment in mRNA vaccine platforms for other infectious illnesses due to the demonstrated effectiveness and quick production of mRNA vaccines.

Growing Oncology Applications: mRNA is being investigated more and more in the treatment of cancer, especially in immunotherapies and customized cancer vaccines that stimulate the immune system to attack tumor cells, which is creating new opportunities for precision oncology.

Market Challenges

High Production Costs: The production of mRNA is costly due to the use of specialized raw materials, cutting-edge technologies, and strict quality control. Accessibility issues are brought on by these expenses, particularly in environments with limited resources.

Cold Chain Logistics:Because mRNA is sensitive to temperature, it must be stored and transported under strict supervision, which raises costs and makes distribution more difficult in underdeveloped areas.

Accessibility and affordability:High production and logistics expenses may limit market penetration, especially for startups and emerging economies, which could impede international growth.

Market Segmentation

By Application

Oncology

Infectious Diseases

Rare Genetic Diseases

Respiratory Diseases

By Region

North America

Europe

Asia-Pacific

Latin America

Rest of the World

Download Our Sample Report Now!

Gain information on Advance Chemical and Material Vertical. Click Here!

Future Outlook

Over the next ten years, the mRNA market is anticipated to develop steadily and significantly. It is anticipated that advancements in transport and manufacturing techniques would improve the stability of mRNA-based products while lowering production costs, increasing their accessibility on a worldwide scale. A new age in medicine is being heralded by the use of mRNA-based remedies for cancer, genetic problems, and respiratory illnesses in addition to vaccinations.

Product development and commercialization are accelerating due to favorable governmental conditions, increased spending by pharmaceutical giants, and an increasing number of clinical studies. It is projected that mRNA will establish itself as a key technology in the creation of next-generation therapies and the provision of healthcare globally as long as these trends persist.

Conclusion

Messenger RNA technology is on track to revolutionize global healthcare with its adaptability, speed, and precision. The market for mRNA is expected to experience revolutionary growth over the next ten years, driven by growing therapeutic uses, robust regulatory support, and advancements in technology. For wider acceptance, it will be essential to remove existing obstacles like exorbitant prices and intricate logistics. mRNA treatments, which are supported by significant investment and innovation, have the potential to treat a variety of illnesses and establish the market as a key component of medicine's future.

0 notes

Text

Breathing Circuit Market Overview: Global Trends and Industry Outlook

The global Breathing Circuit Market is undergoing significant transformation, propelled by technological advancements, increased surgical procedures, and a heightened focus on patient safety. Breathing circuits are essential components of respiratory support systems, facilitating the delivery of oxygen and anesthetic gases to patients while ensuring the removal of carbon dioxide. Their critical role in anesthesia, intensive care units (ICUs), and emergency care has expanded their demand across hospitals, surgical centers, and ambulatory care facilities worldwide.

The market’s expansion is shaped by evolving clinical needs, innovations in design, and regulatory frameworks emphasizing safety and infection control. From disposable single-use circuits to customizable and smart systems, the breathing circuit industry is aligning with global healthcare demands, particularly in the post-COVID-19 environment.

Market Size and Growth Outlook

The Breathing Circuit Market was valued at approximately USD 1.2 billion in 2024 and is projected to grow at a compound annual growth rate (CAGR) of around 5.5% between 2025 and 2032. This steady growth is fueled by:

Rising number of surgeries and ICU admissions

Expansion of healthcare infrastructure in emerging economies

Growing geriatric population with respiratory conditions

Ongoing prevalence of respiratory diseases like COPD, asthma, and infections

Moreover, technological innovation, combined with heightened awareness about infection control and single-use systems, has introduced new growth avenues for manufacturers and distributors.

Key Market Drivers

1. Increased Surgical Volume As global surgical procedures rise—particularly elective and cosmetic surgeries—the need for anesthesia circuits grows. The aging population and rise in chronic illnesses contribute to this trend.

2. ICU Demand Post-Pandemic The COVID-19 pandemic led to a spike in ICU setups globally. Although acute demand has decreased, the emphasis on preparedness has kept investments in critical care infrastructure high.

3. Technological Advancements From integrated humidifiers to closed-loop feedback systems and patient-specific designs, breathing circuits are becoming more sophisticated and tailored to specific medical settings.

4. Shift Toward Disposable Circuits To combat hospital-acquired infections, many healthcare providers are shifting to disposable breathing circuits, especially in high-risk units such as ICUs and operating rooms.

5. Regulatory Compliance and Safety Standards Global health agencies and medical associations are implementing strict guidelines for medical device hygiene, material safety, and design efficiency. This has driven product innovation and quality enhancements across the board.

Global Market Trends

North America: Dominates the market due to advanced healthcare infrastructure, high adoption of new technologies, and a strong regulatory framework. The U.S. leads in both innovation and consumption.

Europe: Significant growth, particularly in Germany, France, and the U.K., where public health systems invest in high-performance critical care equipment. Stringent EU regulations also drive manufacturers to maintain top-tier standards.

Asia-Pacific: Rapid expansion driven by healthcare modernization in India, China, and Southeast Asia. Public-private partnerships and increased medical tourism contribute to rising demand for surgical and respiratory care equipment.

Latin America and Africa: These regions are emerging as potential high-growth markets due to investments in primary healthcare, partnerships with international NGOs, and urban hospital expansion.

Segmentation Overview

The Breathing Circuit Market is typically segmented by:

Product Type: Disposable and reusable circuits

Application: Anesthesia, ICU/critical care, emergency care, neonatal/pediatric care

End-user: Hospitals, ambulatory surgical centers, specialty clinics

Region: North America, Europe, Asia-Pacific, Latin America, Middle East & Africa

Each segment has its unique demand dynamics. For instance, reusable circuits remain cost-effective in lower-income regions, while disposable variants dominate in infection-sensitive environments.

Competitive Landscape

The market is fragmented with both global giants and regional players. Key companies include:

Medtronic plc

Drägerwerk AG & Co. KGaA

GE Healthcare

Teleflex Incorporated

Fisher & Paykel Healthcare

Smiths Medical (ICU Medical)

Ambu A/S

These players compete on innovation, product quality, compliance certifications, and customer service. Collaborations with hospitals, participation in government tenders, and portfolio diversification remain common growth strategies.

Challenges in the Market

Cost Sensitivity in Emerging Economies: Budget constraints can hinder adoption of advanced or disposable circuits.

Regulatory Hurdles: Navigating different compliance requirements across countries adds complexity to international sales.

Raw Material and Supply Chain Disruptions: The global reliance on medical-grade plastics and silicone has made manufacturers vulnerable to supply volatility.

Environmental Concerns: Rising use of disposable circuits creates sustainability challenges due to increased medical waste.

Future Outlook

Between 2025 and 2032, the Breathing Circuit Market is expected to evolve through:

Integration of smart sensors and monitoring systems in breathing circuits

Broader adoption of AI-based ICU management tools

Development of sustainable materials for eco-friendly disposable products

Customizable breathing circuits for pediatric and obese patients

Expansion of OEM partnerships with hospitals and care centers

Conclusion

The Breathing Circuit Market is poised for consistent growth amid rising global health demands, technological breakthroughs, and strategic innovations. As healthcare systems prioritize infection control, cost-efficiency, and patient safety, breathing circuits will remain a vital focus within respiratory care and surgical support. Companies that invest in R&D, sustainability, and regulatory agility will be well-positioned to thrive in the coming decade.

0 notes

Text

Material Handling Equipment Market Outlook Global Trends, Statistics, Size, Share, Regional Analysis by Key Players (2021-2031)

The Material handling equipment market size is expected to reach US$ 92.63 billion by 2031 from US$ 60.05 billion in 2024. The market is estimated to record a CAGR of 6.51% from 2025 to 2031.

Executive Summary and Global Market Analysis

The global material handling equipment market is experiencing strong growth. This is largely due to rapid industrialization, increased warehouse automation, and the expanding e-commerce sector. The market includes a wide array of equipment used for transporting, storing, controlling, and protecting materials throughout various processes, including manufacturing, distribution, and disposal.

The industry's expansion is primarily driven by a growing need for operational efficiency, the increasing adoption of automation technologies, and a demand for better supply chain transparency. In response, manufacturers are developing innovative solutions that integrate advanced technologies like artificial intelligence (AI), the Internet of Things (IoT), and robotics to optimize warehouse operations and logistics infrastructure. Geographically, the Asia-Pacific region leads the market, thanks to significant infrastructure investments and rapid urbanization in countries like China and India.

Download our Sample PDF Report

@ https://www.businessmarketinsights.com/sample/BMIPUB00031690

Material Handling Equipment Market Segmentation Analysis

The material handling equipment market analysis is derived from key segments: technology, material, application, and end user.

By Equipment Type, the market is segmented into:

Cranes and Lifting Equipment

Industrial Trucks

Automated Storage and Retrieval Systems (AS/RS)

Conveying Systems

Racking and Storage Equipment

Automated Guided Vehicles (AGVs)

Bulk Material Handling Equipment

Others

By End-Use Industry, the market is segmented into:

Logistics

Automotive

Construction

Food & Beverages

Pharmaceuticals/Healthcare

Semiconductor & Electronics

By Application Type, the market is segmented into:

Assembly

Transportation

Distribution

Others

Material Handling Equipment Market Drivers and Opportunities

The rapid expansion of e-commerce is a significant driver for the material handling equipment market. As online retail grows, companies like Amazon and Alibaba are investing in automated warehouses to manage high order volumes. This, in turn, increases the demand for equipment such as forklifts, conveyors, and Automated Guided Vehicles (AGVs).

Urbanization and rising consumer expectations for quick deliveries further boost the need for efficient logistics systems. The growth of warehousing in regions like Asia-Pacific and North America directly fuels equipment sales. As e-commerce continues its upward trend, the demand for advanced material handling solutions to streamline operations and reduce delivery times will significantly propel market expansion.

Material Handling Equipment Market Size and Share Analysis

By Equipment Type: Cranes and Lifting Equipment, along with Industrial Trucks, Automated Storage and Retrieval Systems (AS/RS), Conveying Systems, Racking andStorage Equipment, Automated Guided Vehicles (AGVs), and Bulk Material Handling Equipment, are crucial. Cranes and lifting equipment are vital across construction, manufacturing, heavy engineering, automotive, and logistics for efficiently moving heavy materials and payloads. The construction industry, in particular, drives substantial demand due to ongoing urbanization, infrastructure development, and large-scale industrial projects.

By End-User Industry: The global growth of automobile production necessitates efficient material handling systems to manage the flow of materials and finished vehicles within factories and distribution centers. Automotive manufacturing plants are increasingly adopting modernized material handling infrastructure to improve assembly processes, reduce turnaround times, and support lean manufacturing principles, all of which require advanced handling equipment. The automotive industry's adoption of automation, robotics, and IoT-enabled material handling solutions enhances operational efficiency and safety, further boosting the demand for sophisticated equipment.

About Us:

Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Defense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications

0 notes

Text

Torque Vectoring Market : Size, Trends, and Growth Analysis 2032

The Torque Vectoring Market was valued at US$ 10,997.32 million in 2024 and is projected to expand at a CAGR of 10.20% from 2025 to 2032. As the automotive industry pivots toward intelligent, high-performance, and electrified mobility solutions, torque vectoring systems have emerged as a cornerstone of modern drivetrains, significantly improving vehicle handling, safety, and overall driving dynamics.

What Is Torque Vectoring?

Torque vectoring refers to the active distribution of torque to individual wheels or axles of a vehicle, based on road conditions, driver input, and vehicle dynamics. Unlike conventional differentials that passively respond to traction, torque vectoring systems electronically control torque flow, particularly during cornering, acceleration, and slippery conditions.

These systems optimize grip, reduce understeer or oversteer, and allow vehicles to navigate turns more confidently and efficiently. They are found in both all-wheel-drive (AWD) and rear-wheel-drive (RWD) configurations and are becoming increasingly common in electric vehicles (EVs), where electric motors can independently control torque at each wheel.

Key Market Drivers

1. Growing Demand for Enhanced Vehicle Dynamics

Consumers and automakers alike are placing a premium on improved handling, stability, and responsiveness, especially in performance and luxury segments. Torque vectoring systems enable vehicles to adapt to changing road surfaces and dynamic driving conditions in real time, offering an exhilarating yet safe driving experience.

2. Electric Vehicle Integration

In EVs, torque vectoring becomes even more crucial due to the independent motor control available on each axle or wheel. Dual or quad motor EVs, such as those produced by Tesla or Rivian, leverage torque vectoring to maximize traction, range efficiency, and cornering control — all without mechanical differentials.

3. Rise in Safety and Active Vehicle Control Systems

The integration of torque vectoring with advanced driver-assistance systems (ADAS), such as electronic stability control (ESC) and traction control, has strengthened its role in improving road safety. Governments worldwide are encouraging or mandating technologies that minimize crash risks, further boosting market adoption.

4. Performance Optimization in Sports and Luxury Vehicles

Luxury automakers like Audi, BMW, and Porsche were early adopters of torque vectoring, using it to improve drivability, launch control, and cornering precision. The trickle-down of these technologies into mid-range vehicles is expanding the market beyond niche performance models.

5. All-Wheel Drive (AWD) Market Growth

As AWD becomes more common in SUVs and crossovers — the fastest-growing vehicle segments globally — the need for smart torque management systems like torque vectoring increases. These systems optimize power delivery based on terrain, enhancing both off-road capability and on-road comfort.

Types of Torque Vectoring Systems

Active Torque Vectoring: Utilizes electronic controls and actuators to dynamically alter torque distribution in real time. Often integrated with braking and steering systems.

Passive Torque Vectoring: Uses mechanical means such as limited-slip differentials (LSD) or torque-sensing differentials. Less complex and lower cost, but with limited adaptability.

Electric Torque Vectoring (e-Torque): Seen in EVs, where dual or quad electric motors can precisely control torque at individual wheels without any mechanical link.

Key Applications

Passenger Cars: Luxury sedans, coupes, and performance hatchbacks benefit from better road grip, agile handling, and enhanced cornering capability.

SUVs and Crossovers: Use torque vectoring to improve traction on varied terrains and ensure driver confidence in challenging weather conditions.

Electric Vehicles (EVs): Especially relevant in AWD EV platforms, where multiple motors can digitally distribute power with extreme precision.

High-Performance and Sports Cars: Key selling point for dynamic performance and track handling. Improves lap times and enhances stability at high speeds.

Commercial and Utility Vehicles: Still a niche, but growing interest in improving cargo safety and ride stability during dynamic load shifts.

Regional Insights

North America: Leads in adoption due to strong presence of performance vehicle manufacturers and growing EV deployment. The U.S. remains a key market.

Europe: A mature and competitive market where premium and performance brands integrate torque vectoring as a standard or optional feature. Tight safety regulations and technological innovation drive growth.

Asia-Pacific: Rapidly growing market, especially in China and Japan, where EVs and AWD SUVs are expanding. Government incentives for advanced technologies contribute to regional demand.

Latin America and Middle East & Africa: Smaller but emerging markets with gradual adoption as vehicle sophistication and consumer expectations rise.

Competitive Landscape

GKN Automotive Limited

A leader in driveline systems, GKN supplies advanced torque vectoring solutions to global OEMs. Known for its Twinster system that uses clutches instead of differentials for torque control.

BorgWarner Inc.

Offers active torque management systems and is investing heavily in electrified drivetrains, positioning itself strongly for the EV market.

ZF Friedrichshafen AG

Provides a wide array of driveline technologies including torque vectoring systems. Their focus on modular systems suits multiple vehicle classes.

JTEKT Corporation

Through its Koyo brand, JTEKT develops torque vectoring differentials and steering systems, emphasizing performance and fuel efficiency.

American Axle & Manufacturing Holdings, Inc. (AAM)

Well-regarded for its e-AAM driveline technology, which supports hybrid and electric applications with precision torque management.

Dana Incorporated

Provides integrated torque vectoring and electric propulsion systems. Focuses on scalable solutions for both traditional and electrified vehicles.

Market Trends

Software-Defined Vehicle Controls: Increasing reliance on advanced software for torque management, enabling over-the-air (OTA) updates and adaptive behavior based on real-time data.

Electrification of AWD Systems: Mechanical AWD is giving way to electric torque vectoring in EVs, simplifying drivetrains and enhancing control.

Integration with ADAS and Autonomy: Torque vectoring is becoming a foundational technology for autonomous vehicle control and advanced safety systems.

Aftermarket Interest: Enthusiasts and tuners are exploring retrofitting torque vectoring solutions for performance gains in conventional cars.

Browse more Report:

Mass Flow Controller Market

Manufacturing Scale Electrostatic Precipitator Market

Lipid Nanoparticle Raw Materials Market

Kinesiology Therapeutic Tape Market

Intelligent Traffic Signal System Market

0 notes

Text

High-Performance Resin and Epoxy Solutions by Leading Resin Manufacturers in Mumbai – DRC Resins India

Resins play a vital role in multiple industries, from construction to electronics, automotive, marine, and even furniture manufacturing. Among the growing number of manufacturers in this segment, DRC Resins India stands out as a trusted name. As one of the leading resin manufacturers in Mumbai, the company offers a wide spectrum of high-performance resins, including resin coating, resin for adhesive, and epoxy resin solutions tailored to industrial requirements.

Resin Manufacturers in Mumbai: The Growth of a Trusted Industry

Mumbai has emerged as a significant hub for specialty chemical and resin manufacturing. With access to ports, advanced infrastructure, and a technically skilled workforce, resin manufacturers in Mumbai serve both domestic and international markets. DRC Resins India is known for its consistent innovation, high-quality standards, and timely delivery.

The company supplies a wide variety of resins used in coatings, adhesives, sealants, and composites. Its facility incorporates R&D, quality control, and scalable manufacturing to meet large and small batch requirements. DRC’s product line is built to meet the ever-changing demands of industries such as construction, infrastructure, electronics, and industrial flooring.

Resin Coating: Strength, Protection, and Longevity

Resin coating serves as a protective and aesthetic layer across various surfaces. DRC Resins India formulates coatings that resist abrasion, chemicals, weathering, and UV exposure. These coatings are commonly applied over concrete floors, metal surfaces, wood, and fiberglass.

Whether applied in industrial plants, warehouses, or showrooms, resin coatings help improve longevity and reduce maintenance costs. The formulation ensures strong adhesion, smooth finish, and quick curing—making them ideal for fast-paced projects. DRC’s coatings are developed to perform under both heavy load-bearing and chemical-intensive environments.

Resin for Adhesive: High Bonding Strength Across Materials

DRC Resins also specializes in resin for adhesive applications. Adhesive resins must provide strong bonds between a wide range of substrates including metal, plastic, wood, ceramics, and composites. The adhesives made using DRC's resins provide high tack, excellent peel and shear strength, and resistance to water, chemicals, and heat.

These resins are used in packaging, electronics assembly, automotive parts, construction joints, and DIY markets. DRC’s products can be formulated for both pressure-sensitive and structural adhesive needs. By controlling viscosity, cure time, and mechanical strength, these resin formulations enable versatile bonding in industrial environments.

Epoxy Resin: Performance-Driven Industrial Applications

Among the broad resin categories offered by DRC Resins India, epoxy resin holds a significant place. It is well-known for its excellent mechanical properties, chemical resistance, dimensional stability, and electrical insulation. These characteristics make epoxy a preferred choice for coatings, adhesives, encapsulants, laminates, and composite materials.

DRC manufactures both standard and customized epoxy resin solutions tailored to specific industrial needs. These resins cure at room or elevated temperatures and are compatible with a wide range of hardeners. The finished products deliver performance that withstands mechanical stress, exposure to chemicals, and long-term wear.

Epoxy Resin for Adhesive: Durable and Versatile Bonding

The demand for epoxy resin for adhesive is increasing across manufacturing sectors. DRC Resins India offers epoxy adhesives with high bonding strength, moisture resistance, and temperature stability. These adhesives are used in structural applications such as panel bonding, composite joining, and metal-to-metal assembly.

Applications range from electronics and appliances to transportation and renewable energy. Epoxy adhesives are particularly valuable in scenarios where mechanical fasteners or welding are not suitable. With controlled cure speeds and high modulus strength, DRC’s epoxy-based adhesives are engineered for durability.

Epoxy Resin Adhesive: Structural Integrity and Chemical Resistance

In industrial use, epoxy resin adhesive provides the mechanical integrity necessary for safety and efficiency. DRC’s formulations bond a wide array of substrates and are designed to endure thermal cycling, impact, and moisture ingress.

These adhesives cure to form a rigid, durable bond capable of bearing heavy loads, making them suitable for automotive frames, aerospace parts, marine composites, and civil engineering structures. They also show excellent adhesion on oily or slightly contaminated surfaces—an essential advantage in production lines or field repairs.

DRC Resins India also offers variants with added flexibility, low shrinkage, and resistance to fuels, oils, and corrosive chemicals. The company tailor’s formulations to align with environmental regulations and industry-specific requirements.

Epoxy Resin Industrial Flooring: Seamless Strength Underfoot

For industries requiring robust flooring, epoxy resin industrial flooring delivers unmatched benefits. From factories to showrooms, laboratories to hospitals, epoxy flooring ensures hygienic, smooth, and chemical-resistant surfaces.